ARTICLES

By Ramesh Natarajan

•

September 23, 2025

Battery manufacturing is often seen as a purely technical process — involving chemical reactions, grid casting, pasting, curing, assembly, and charging. But in reality, it is equally a business of human decisions, operational discipline, and financial strategy . In this article, adapted from my recent podcast episode, I share 11 practical guidelines for battery manufacturers . These are not just best practices — they are survival strategies for anyone working in the battery industry or planning to enter it. 1. Master Battery Chemistry Every successful battery begins with the right chemistry. A deep understanding of electrode behaviour, electrolyte reactions, and specific gravity changes is essential — not only for R&D but also for production and troubleshooting. Chemistry is the foundation of battery performance and innovation . 2. Standardize and Follow Processes Production parameters are not just rules — they are safeguards for consistency. Deviating from established procedures on the shop floor often leads to quality problems. Continuous improvement is welcome, but it must be tested and validated. 3. Think Like a Systems Engineer Battery production is a chain of connected processes. A grid casting machine has little value if the pasting or curing stations are under-resourced. Balancing upstream and downstream operations prevents bottlenecks, idle inventory, and delivery delays. 4. Treat Inventory as Cash In the lead acid battery industry , inventory ties up huge amounts of working capital. Excess stocks of lead, lead oxide, or separators are frozen money. Managing inventory efficiently is critical for controlling costs and ensuring smooth cash flow. 5. Never Compromise on Quality Cutting corners may reduce immediate costs but damages long-term credibility. Warranty claims and customer dissatisfaction are far more expensive than maintaining strict quality control. In today’s competitive market, quality is your strongest differentiator . 6. Build a Culture of Training People forget procedures or develop shortcuts that affect quality. Ongoing training, retraining, and skill development ensure that your workforce follows best practices consistently. A culture of continuous learning is a competitive advantage. 7. Minimize Waste and Scrap Lead is one of the most expensive raw materials in the battery industry. Scrap, rework, and pilferage eat directly into margins. By identifying and reducing non-value-adding activities, manufacturers can significantly improve profitability. 8. Maintain a Long-Term Perspective The battery business is not a quick-profit venture. Success requires resilience, patience, and the ability to zoom out from day-to-day operations to focus on long-term strategy, customer relationships, and market positioning. 9. Differentiate Between Cash Flow and Profit High sales volumes don’t always equal profitability. With raw material costs, especially lead prices, changing frequently, manufacturers must adopt dynamic costing systems. Otherwise, you risk selling at a loss without realizing it. 10. Build Strong Relationships Technology alone doesn’t sustain a battery company. Strong partnerships with employees, vendors, and customers are equally important. Trust and fairness create loyalty, which helps businesses withstand market fluctuations. 11. Know When to Exit Battery manufacturing demands high energy, commitment, and responsibility. If passion fades or returns no longer justify the effort, it’s wise to plan an exit. Staying beyond that point often drains resources and enthusiasm. Final Thoughts Battery manufacturing is not just about machines and materials — it is about people, processes, and principles . These 11 guidelines provide actionable insights that textbooks rarely cover but real-world experience proves vital. 📌 Grab your FREE Battery Manufacturing Process Flow Chart here: 👉 Download Here 🌐 Read more blogs, listen to podcasts, and watch videos on battery manufacturing: 👉 www.rameshnatarajan.in 📩 Share your thoughts or queries with me directly at: 👉 rameshnkailad@gmail.com 📚 Get my books on batteries and industry practices: 👉 Buy Book 1 👉 Buy Book 2 — By Ramesh Natarajan, Author of the Amazon Bestseller “Batteries Demystified” , Podcaster & Blogger

By Ramesh Natarajan

•

August 12, 2025

In recent years, lithium-ion batteries have become the poster child for innovation in the energy storage industry. From powering our smartphones to enabling electric vehicles, their rapid adoption has made many believe they will soon replace lead-acid batteries entirely. But is that really the case? While lithium-ion technology offers undeniable advantages in certain applications, the idea that it will completely replace lead-acid batteries is, in my view, unrealistic and impractical. Let’s explore why. Where Lithium-Ion Batteries Shine Lithium-ion batteries have proven their worth in areas where lightweight design, compact size, and fast charging are critical. Consumer Electronics: Smartphones, laptops, drones, and cameras. Electric Vehicles (EVs): Reduced weight equals better range and performance. Portable Tools & Medical Devices: High energy density makes them ideal. In these areas, lithium-ion’s quick charging capability and low maintenance requirements (no frequent water topping-up) are strong selling points. Why Lead-Acid Still Holds Strong In sectors like UPS systems, renewable energy storage, and material handling equipment (MHE) , factors such as safety, cost, and reliability outweigh the benefits of lightweight design and fast charging. Lead-acid batteries have been refined over decades to handle demanding conditions with predictable performance. Automatic water top-up systems have solved one of their biggest past drawbacks — manual maintenance. Many high-quality lead-acid batteries now achieve 1,200–1,500 cycles in MHE applications, meeting global IEC standards. The Reality of Lithium-Ion Limitations While lithium-ion manufacturers often claim 1,500–4,000 cycles , this comes with conditions — perfect battery management systems (BMS), controlled temperature, and optimal charging patterns. In real-world heavy-duty use (e.g., forklifts), users report: Capacity loss due to cell imbalance . Costly maintenance and cell replacement . Downtime during servicing. In contrast, lead-acid batteries are simpler to maintain and globally recyclable . Recycling networks for lithium-ion batteries are still developing, raising environmental concerns. Cost, Safety & Total Cost of Ownership (TCO) When it comes to energy storage systems , especially in industrial and large-scale applications: Lead-acid wins on cost and TCO. Lithium-ion may offer compactness , but with higher upfront and maintenance costs. Lead-acid batteries are inherently safer with fewer thermal runaway risks. Environmental Impact & Recycling Lead-acid batteries have a well-established recycling process — often with buyback or scrap rebates. Lithium-ion recycling is still in its infancy, and without robust infrastructure, discarded cells can become an environmental hazard. The Final Verdict Lithium-ion batteries are here to stay, but they won’t replace lead-acid batteries anytime soon. Each technology serves distinct needs: Lithium-ion: Best for weight-sensitive, compact, and portable applications. Lead-acid: Best for cost-sensitive, safety-critical, and high-reliability industrial applications. Unless a safer, more cost-effective, recyclable alternative emerges, lead-acid batteries will continue to be a dominant player in the energy storage industry for years to come.

By Ramesh Natarajan

•

December 14, 2023

Battery claims are due to damage, improper maintenance, abuse, incorrect handling, and misuse. The possible reasons for the explosion of a lead acid battery can be either one or a combination of the following: ✅ The battery can explode if it is subject to an overcharge i.e., charged continuously though it is fully charged. When a battery is fully charged it means the active material has converted to sponge lead on the negative plates & lead dioxide on the positive plates. In such a condition, no lead sulfate active material is available to be converted chemically on both positive & negative plates. The electrical energy fed by the charger which is supposed to be converted to chemical energy is converted to heat energy. The electrolyte is heated & the evolving explosive hydrogen gas generated builds up pressure under the vent plugs causing the vent plugs to pop up or builds up pressure sufficient enough to explode the battery. ✅ The battery can explode if an improper charger is used to charge the battery. When a battery is connected to a charger meant for charging a larger capacity, the charger starts charging the battery at a higher-than-recommended current. In such cases, the battery life is affected and the active material from the plates starts shedding creating an internal short. The internal short causes heat and explosion. In this case, the internal short is not because of a manufacturing defect but due to incorrect charger selection. ✅ The battery can explode if sources of static electricity cause a spark in the vicinity of the batteries. Also, naked flames or welding sparks, or any other sparks near batteries while batteries are on charge can cause a fire or explosion. As and when batteries are on charge hydrogen gases are evolved. Hydrogen gas is very flammable and yields explosive mixtures with air and oxygen. Since hydrogen gas is flammable the source of spark with oxygen from the atmosphere can lead to a fire and explosion of the battery. Hence even smoking cigarettes is not recommended in rooms where batteries are on charge. ✅ The battery can explode if the batteries are on charge in a room with improper ventilation. When batteries are on charge hydrogen & oxygen are both evolved as gases. They do recombine to form water but not fully. If the hydrogen gas is evolved to such an extent that the concentration of hydrogen gas is greater than 4% it can cause an explosion of the battery. Hence batteries must be charged in an atmosphere where the gases can escape. The battery manufacturers usually recommend battery charging areas or rooms have adequate ventilation with at least six air changes per hour. ✅ The battery can explode if batteries of smaller than recommended size or lower Ah capacity are used. At times — due to the non-availability of correct capacity batteries or cost considerations — batteries of lower capacity are fitted to equipment or vehicles. In such cases the charger being of a much larger capacity than required by the battery –tends to overcharge the battery, heating the battery, causing bubbling & gassing with a possible explosion of the battery due to pressure build-up within the battery container. ✅ The battery can explode if battery terminals are shorted externally with any metal object or conducting substance. ✅ The battery can explode if the battery has an internal shorting due to a manufacturing defect. ✅ The battery can explode if the vent holes of vent plugs are clogged due to the battery being kept or used in a dusty/dirty environment. The batteries having such clogged vent holes of vent plugs shall not allow gases to escape due to which there shall be pressure build-up leading to an explosion. Please share my answer if you found it to be useful. Do follow me for more such articles. You can visit my website to 👀read similar blogs and articles, 👂hear my podcasts, and 🎥see videos about batteries and related subjects by clicking the link below: ✔️ www.rameshnatarajan.in TO GRAB YOUR FREE COLOR COPY OF THE BATTERY MANUFACTURING PROCESS FLOW CHART, CLICK ON THE LINK BELOW: ✔️ https://ramesh-natarajan.ck.page/1d1909eaef To✍️write to me with your comments and suggestions please do note my E-Mail given below: ✔️ rameshnkailad@gmail.com To buy my books 📒, please click on one of the links below: ✔️ https://relinks.me/9390661692 ️or https://relinks.me/B0BNXL1854

By Ramesh Natarajan

•

October 2, 2023

➡️Are you a battery manufacturer selling batteries in the retail market? ➡️Are you a dealer of batteries? ➡️Are you finding the market conditions unfavorable? ➡️ Are you struggling to manage offered warranties & replacement? ➡️Are you frustrated with the business setup? ➡️Are you finding the competition tough? ➡️Are you facing unfair demands from the battery user? ➡️Are you finding difficulty in maintaining committed Price Line, even for short buying cycles ? 👉 If yes, then you must consider 👀 reading this article. Are you finding it difficult to sell batteries in the retail market? IF YES, DO READ THIS TO PAUSE & INTROSPECT. Then sit back and think. 1. What does your customer want? 2. He wants batteries or the output from batteries? We need to understand that batteries store energy, and the user of batteries is only interested in this stored power. Let us understand what the customer does not like about buying batteries. 1. All batteries, even unbranded ones, are expensive. 2. Batteries need maintenance. AMC is cumbersome and an additional task in addition to cost. 3. Battery buying is an activity that is best avoided and is boring. 4. The offers of different battery manufacturers are confusing. 5. Dealers selling unbranded batteries keep shifting loyalties. 6. Branded batteries are costlier than unbranded batteries. Next, understand the customer of today. 1. He or she is looking for reliable and trouble-free service. 2. He/she is ready to pay—an EMI and not a lump sum. 3. He or she does not want to be committed in many matters. Batteries are not considered an asset anymore but a necessary evil. 4. His or her job entails shifting for work from cities and even countries at times. Observe the trend. 1. Ola and Uber are convenient and hence have succeeded as concepts. 2. I Phones and other costly smartphones sell more easily on EMI than against full payment. 3. Netflix and Amazon Prime OTT platforms are examples of subscription-based services that are popular. What needs to be done? Battery manufacturers need to come together and have an app developed that can onboard battery dealers. Probably inverter and solar system integrators, who sell batteries too, can be part of this network. An app developer can make this app independently if the battery manufacturers do not want to invest in software development and maintenance of the app. App development is not the forte of battery manufacturers anyway. The marketing of this app, which is like a Zomato or Swiggy app, is then the job of the app developer. Customers or users of batteries need to be registered on this app for the service they need. The battery sellers can then make suitable offers to the prospective battery user. The battery dealers can, in fact, onboard prospective battery customers onto this app. Once the credit card is swiped, payment shall be done monthly until the service is availed. Basically, the entire system should work like an electricity utility company. Or like a newspaper or magazine subscription. The app developer benefits from the subscription fee from the battery seller, and the battery seller benefits from the battery users’ monthly payments. The app can communicate with the BMS and give periodic alerts. A GPS can be incorporated as part of the system to provide alerts in case of a battery and inverter. The app can be made with all the inputs needed. The onboarding of users should happen with 1. One-time immediate payment for installation and commissioning in the case of automotive batteries or necessary wiring in the case of inverter/solar batteries. 2. A security deposit of the battery or battery and inverter can be collected as a reserve future payment by credit card and not as a lump sum payment. 3. Monthly payment of the EMI setting may be done. All these can happen with credit card details. 4. On receipt of the monthly payment, the security deposit must be reduced accordingly. 5. The OTP method commonly used nowadays can be used for the start and discontinuation of service. 6. Discontinuation of service terms can be equated to the cost of the system and the expected life of the battery. 7. The cost of the scrap battery, which is in good working condition, needs to be factored into the system properly—as a lump sum rebate for the next cycle or as a free service for extra months in this or the next cycle. 8. Terms for discontinuation of service in between can be decided and incorporated into the app. Users can use this working system and the app for 1. automotive batteries, 2. inverter batteries, 3. inverters and batteries, 4. UPS systems, 5. solar batteries, 6. lift batteries in residential complexes, 7. golf cart batteries, 8. scrubbers, 9. battery rental services, 10. forklifts and other MHEs like pallet trucks or scissor lifts. In fact, the biggest buyers of motive power batteries as well as material handling equipment are rental companies that provide service to large industries and warehouses. The users of this service do not employ drivers for three shifts. This is the responsibility of the service provider. In fact, they do not have to worry about maintenance. They only provide space for charging the batteries and the required electric points for the charger. Even the charger and charger maintenance are in the purview of the service provider. This model of the MHE segment is probably what inverter, solar, and other segment battery manufacturers have to follow and implement. How do inverter battery manufacturers benefit? Presently the competition in the market and price war amongst competitors is leading to the closure of many manufacturing companies. The quality of batteries is the first casualty. Once this system of providing stored energy starts, every manufacturer benefits. The ones using required quantity of lead and good technology to make batteries shall earn monthly EMI payments for a longer duration from the same battery. Others compromising on raw materials quantity and quality shall have batteries working for fewer months. As far as the user is concerned the per month cost shall be uniform. This shall be a Win-Win situation for both the battery manufacturer and the battery user. The competition amongst battery manufacturers shall now be a healthy competition to make longer-lasting batteries. With the cutthroat competition consigned to the dustbin, the industry shall surely survive according to me. Does the above formula apply to all battery manufacturers? No. Manufacturers exporting batteries, selling to government agencies or supplying in bulk have no issues and are not part of the retail market. They need to compete at a different level and are in a different market altogether. Hence these battery manufacturers can continue with direct sale of batteries. The other manufacturers catering to retail may have to rethink their strategy and adopt this or some other better idea. What could be a better idea? A better idea may be having an entire residential society have renewable energy or power from a UPS with metered power in each apartment. This is similar to the piped gas system. A still better idea may be a smart hybrid system for residential complexes. Utility power has to be used only when renewable energy is not available. The utility can be on standby to top up the power requirement based on load. This facility, however, will need to be implemented at the time of the construction of the apartments. As with any new scheme or proposal, this is an idea that needs to be worked upon and honed to perfection. Efforts from all stakeholders will surely benefit the battery manufacturers, who are struggling to sell batteries in the retail market. You can visit my website to 👀read similar blogs and articles, 👂hear my podcasts, and 🎥see videos about batteries and related subjects by clicking the link below: ✔️ www.rameshnatarajan.in To✍️write to me with your comments and suggestions please do note my E-Mail below: ✔️ rameshnkailad@gmail.com To buy my books 📒, please click on one of the links given below: ✔️ https://relinks.me/9390661692 ️or https://relinks.me/B0BNXL1854 ✅Please click on the link below and read the article: https://medium.com/@rameshnkailad/are-you-a-battery-manufacturer-849cc913db44 Please follow me on medium so that you do not miss the articles and blogs posted by me regularly on Medium .

By Ramesh Natarajan

•

June 2, 2023

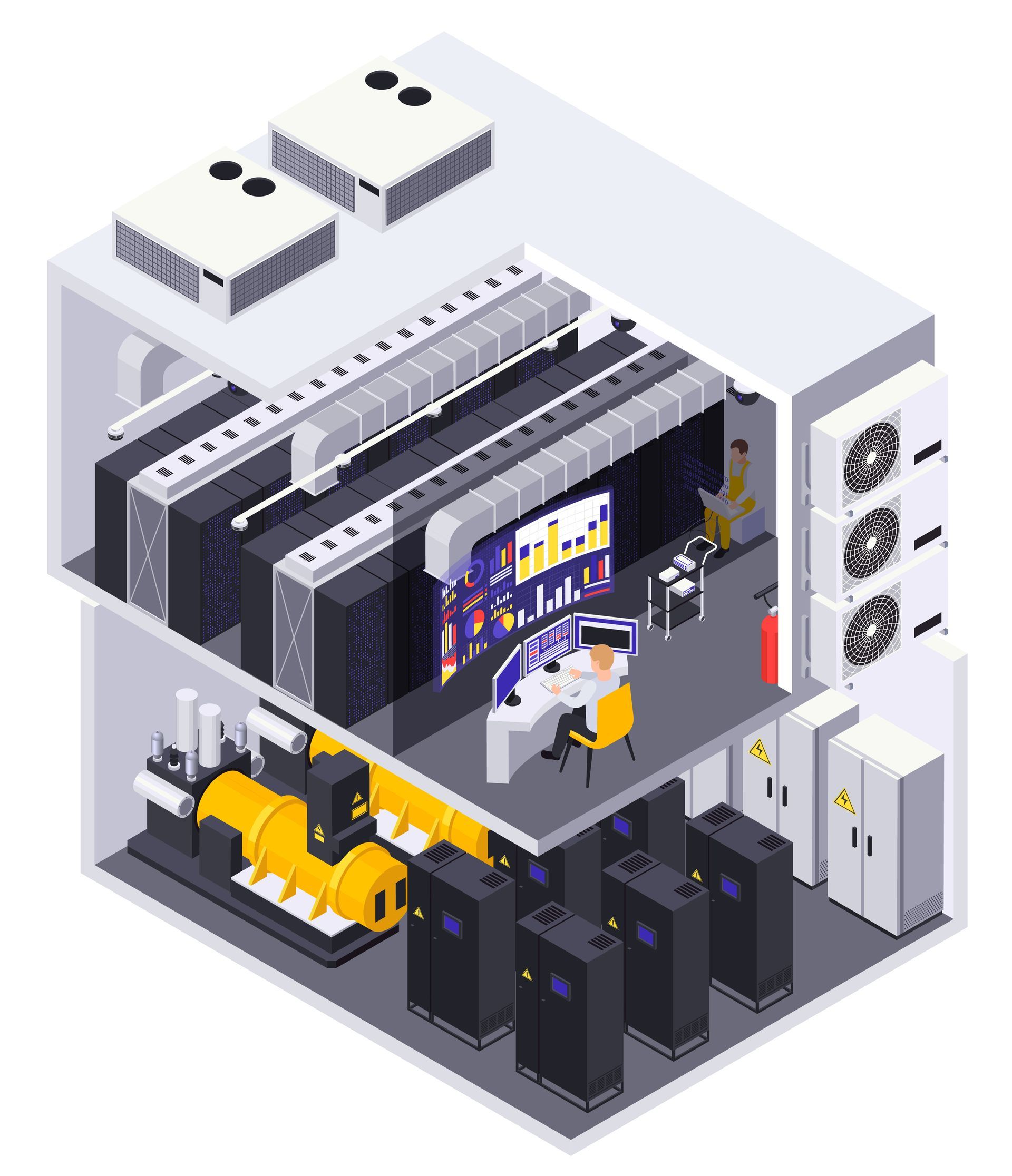

A large number of lead acid batteries are used for stationary applications in high-capacity UPS systems to power the load in case of a power outage. Such large UPS systems with a lot of batteries can be found in hospitals, offices, large industries, power sub stations, nuclear power installations, railways and defence organizations. In these places the power outages are not acceptable and quality power is an absolute requirement. A lot of lead acid batteries are used for motive power applications in industries, airports, nuclear power stations, railways, docks, ordnance factories, godowns, ports, warehouses etc. where heavy materials are handled. These motive power batteries known as traction batteries are used to power forklifts, pallet trucks, platform trucks, scrubbers, industrial sweepers and automated guided vehicles or die loaders. The stationary batteries, as the name implies, are housed in rooms, and used in these rooms at the time of charge as well as discharge. In the case of traction batteries, these are generally used on vehicles, but usually charged in a location, wherein, all the batteries return at the end of a shift for a recharge. Thus, these batteries also have a dedicated battery room for charging. In both the above instances, where stationary or traction batteries are used, the batteries are usually allotted dedicated battery rooms. The users of batteries, often times, look up to the battery manufacturer for recommendations, as regards battery room design. The engineer who visits the site and interacts with the user, must also be preferably aware of the battery room design. A good battery room must be designed to adequately take care of - Corrosion related problems - Ventilation requirements - Battery room illumination - Drainage & effluent collection - Safety w.r.t. fire & explosion - Emergency exits - Safety boards, drills & signages - First aid facilities specially to attend to acid splash in eyes The electrolyte, sulphuric acid being highly corrosive, the flooring is likely to get damaged due to acid spills. Hence it is highly recommended that acid resistant, skid proof special vinyl (PVC) flooring is used. Please note that the thin decorative vinyl flooring, with joints at various places, is not suitable. The flooring required is of industrial grade, in roll form. It has to be laid with minimal joints & with a possibility of sealing of joints. This has to be stuck to flooring with sufficient gradient, sloping towards drains, so that, the flooring can be washed, to allow the waste water to flow into a collection tank. The drains and tanks also need to be fused to the flooring by welding. As regards ventilation requirements the room must have sufficient windows or exhaust fans to ensure that the gases evolved during charging are vented out. Care must be taken to ensure that the windows are kept closed, if the exhaust fans are fitted to the windows. This will ensure that the fresh air coming in from the windows are not exhausted out, thereby leaving the gases evolved from the batteries, to remain in the room. The windows with glasses may be required for natural lighting and can remain closed in normal times, when the exhaust is ON. These windows can be opened to remove the gases evolved from the batteries, when the exhaust fans are not installed or are not working due to some reason. The room must have fresh air inlet, such that, this air comes in from an area opposite to that of the exhaust location. It is highly recommended that hydrogen sensing alarms are installed in battery rooms, since the hydrogen gases evolved during charging of the batteries, is explosive in nature and is the main cause of battery fires. A concentration of over 4% hydrogen is the cause of fires and an audio-visual alarm can alert the user of batteries, much in advance. Such an alarm annunciation, enables the user to do the needful to avert the fire, by stopping the charging or clearing the room of Hydrogen. The user can operate additional exhaust fans or take necessary measures as deemed fit. In certain organizations the exhaust is connected to the hydrogen sensors such that they operate intermittently with an arrangement that these fans are switched on only when the hydrogen gas accumulates to a preset level – much below the 4% danger level. Battery rooms need to be sufficiently lit since the readings of voltage, specific gravity, electrolyte level need to be taken periodically and recorded – to obtain long life from the battery. This being a requirement the lighting used in the rooms need to be adequate and corrosion resistant too. The acid fumes must not corrode the fittings. Hence the lights must be such that they have PVC covers with no possibility of acid fume ingress. There has to be a light arrangement of the portable type to enable the maintenance engineer to check the batteries. Additionally, torches have to be available for checking electrolyte level in the cells or for inspecting the cells through the vent holes. Battery rooms need to be washed periodically to keep the floor clean and at all those times when the acid spills on the floor. Since the wash water, which is bound to be acidic in such instances, has to be drained out, without stagnating and being a cause of accident due to slippage on a wet floor, the design of the battery room floor has to be made, with a slope towards the drain. Gutters need to be made with a slope towards a collection tank. All these, the drains, gutters and collection tank, need to be lined and fused with the acid resistant floor. The collection tank can be emptied periodically and the acidic water can be neutralized before a proper disposal, in line with the regulatory norms. The battery room must not have any hanging wires and all electrical wires must be properly secured and bunched together in case they cannot be laid through cable trays due to some reason. Such bunched cables must not be in pathways and must be restricted to the space between the charger and battery with clear demarcation. Necessary fire extinguishers must be available at various locations for emergency use. Buckets filled with sand must also be kept at various locations for emergency use in case of a fire. Fire alarms and necessary outlets for water to put OFF the fires must be available since lead acid battery fires can be put OFF using water after switching OFF all electrical equipment and switchgear. The chargers and electrical connections must have proper tripping facilities to disconnect and switch OFF in case of a fire. All battery charging rooms must be designed with emergency exits since a single entry and exit is a very dangerous situation. The exits must be on opposite sides and must preferably lead to the open and not to another room which may be housing the charger or load connected to the battery room. Multiple emergency exits shall be better since a fire can also cause explosions with lead shrapnel causing grievous injury to people trapped inside in case of a fire. The room must have safety boards giving clear instructions as regards the safety parameters and work discipline to be followed. The standard operating procedures (SOPs) must be in the local language and additionally in English / Hindi whichever is the widely spoken and understood language. There must be appropriate signages guiding personnel to the emergency exits and wash rooms and towards the first aid facilities. Regular safety drills must be conducted and training must be imparted periodically to personnel working with batteries. At times a simple operation like checking of specific gravity if not done carefully can result in acid splash into the eyes. In such cases it is important to urgently splash eyes with water to prevent damage to the eyes. Hence it is recommended that an arrangement be made available to rinse the eyes with water. Such safety equipment for rinsing eyes is available and need to be preferably fitted near the battery rooms. A first aid kit to take care of burns due to fire with gauze cloth and other medicines must also be available near the battery room. These must not be in the battery room if there is a possibility of them being corroded. The battery room designed, taking the above points into consideration, shall solve a lot of issues for the battery user. A service engineer or maintenance department personnel taking care of batteries must be aware of the above requirements as regards battery rooms. To get in touch with me please click on the link below: https://linktr.ee/rameshnatarajan